■ CAE(Computer Aided Engineering) support

PRET Advanced Material’s CAE(Computer-Aided-Engineering) team partners with customers to evaluate the design and tooling and to tailor an optimized solution for their specific design, tooling and process.

PRET’s State-of-the-Art CAE capabilities helps our customers to prevent multiple iterations of trial and error in the design, engineering, tooling modification and testing. This helps to significantly improve the efficiency of the design and validation process, which in turn, provides both a time and cost savings to the customer.

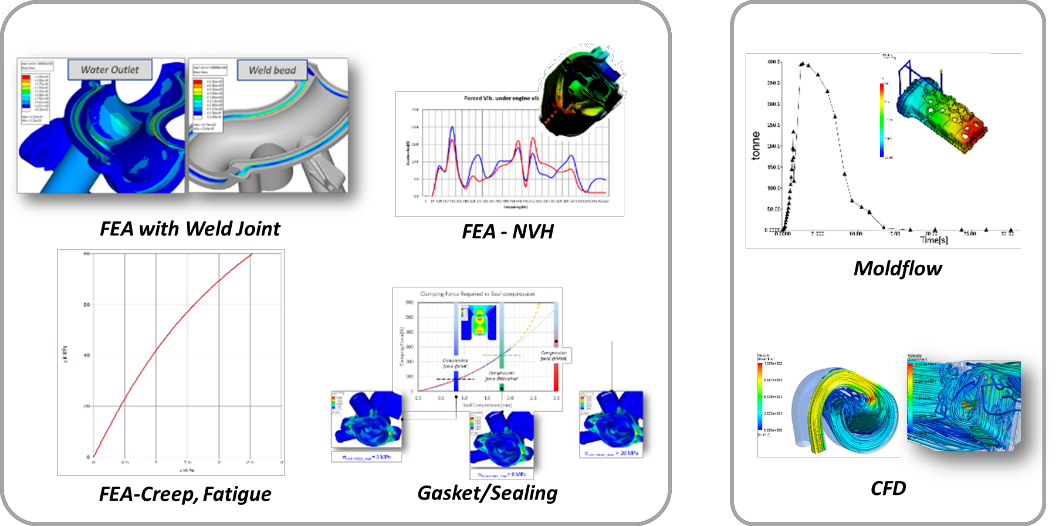

We utilize broad range of CAE software to best support customer’s needs that include injection molding simulation, structural, NVH, thermal, creep, fatigue analysis and so on.

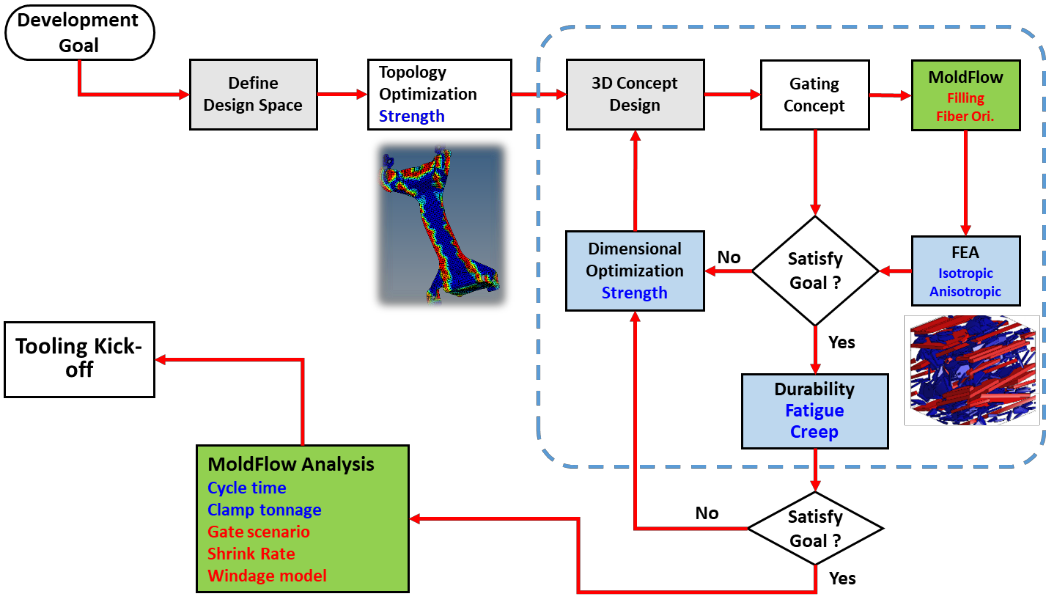

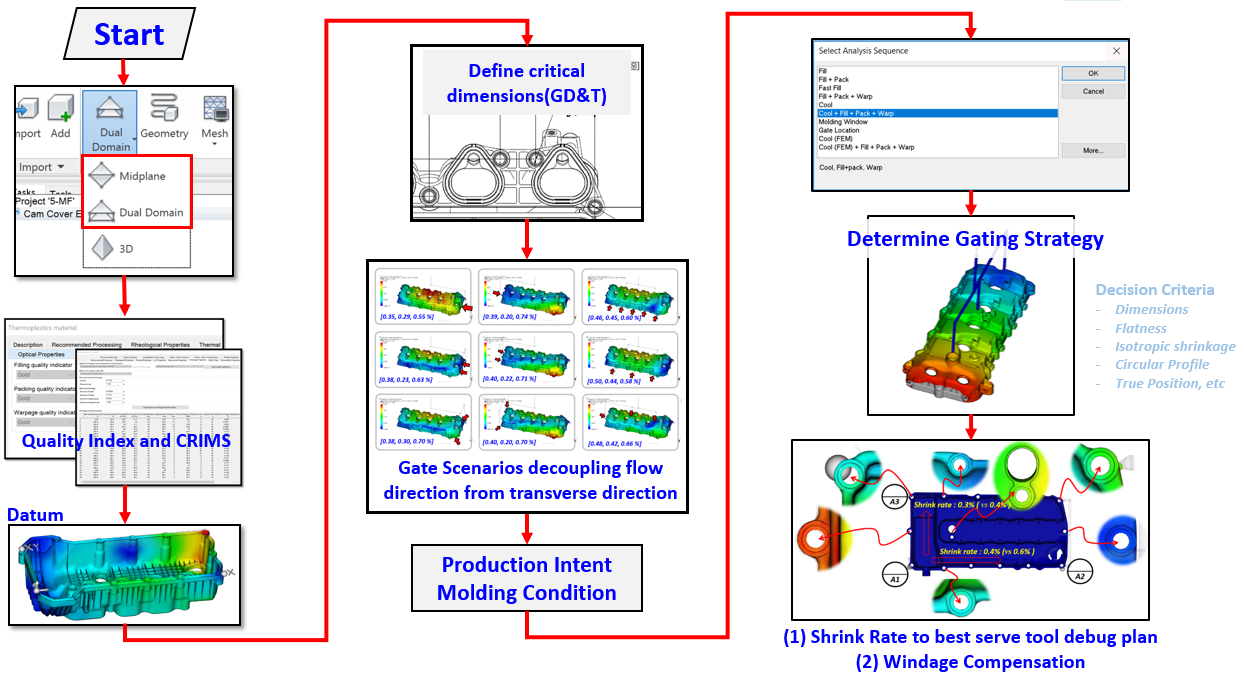

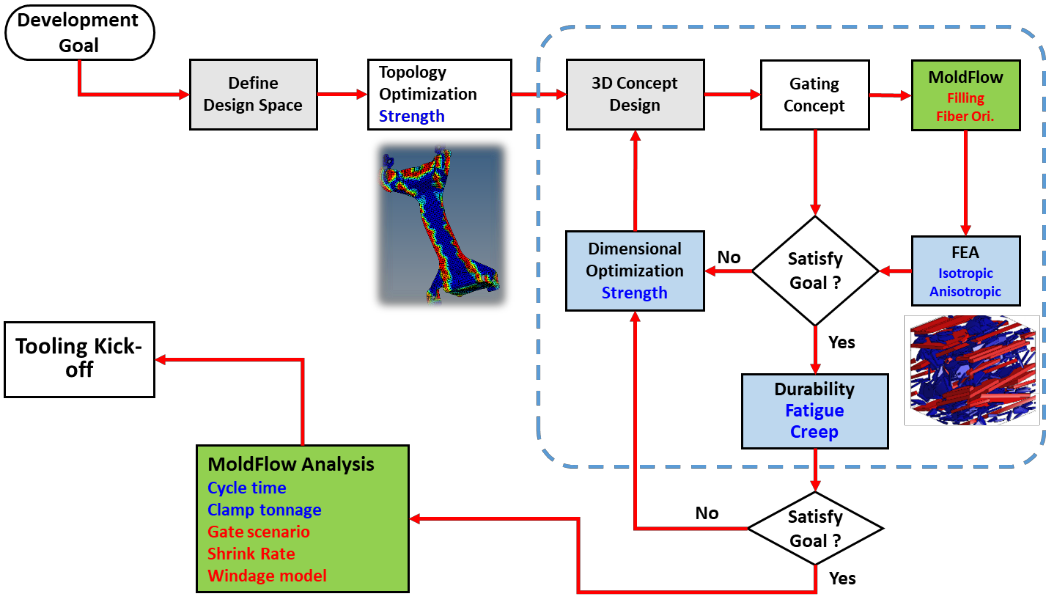

● Injection Molding Simulation

PRET collects waste carpet to reclaim into high performance PA6 and PA66 Ecolon grades. However, adopting alternative materials in the injection-molding environment is not always simple.

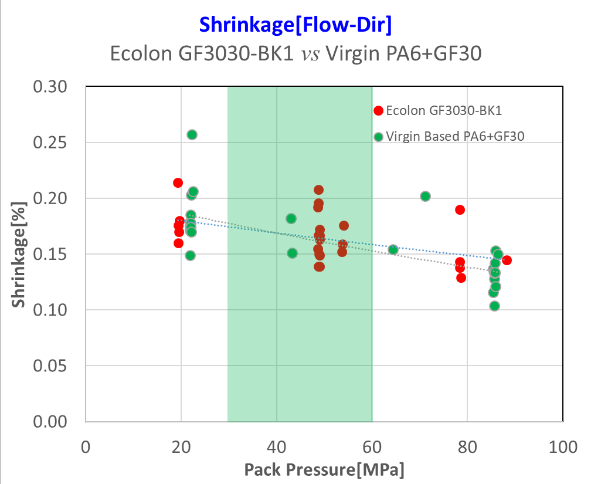

High crystallinity of carpet fiber which is produced through high speed spinning process tends to make our carpet based Ecolon grades shrink slightly differently from typical virgin based PA6 and PA66 materials.

Slightly different shrinkage behavior makes different dimensional prediction from virgin based material.

When switching to our Ecolon or Wellamid recycled material from a virgin material, critical factors for success include speed and ease of making the change with no or minimum tooling changes.

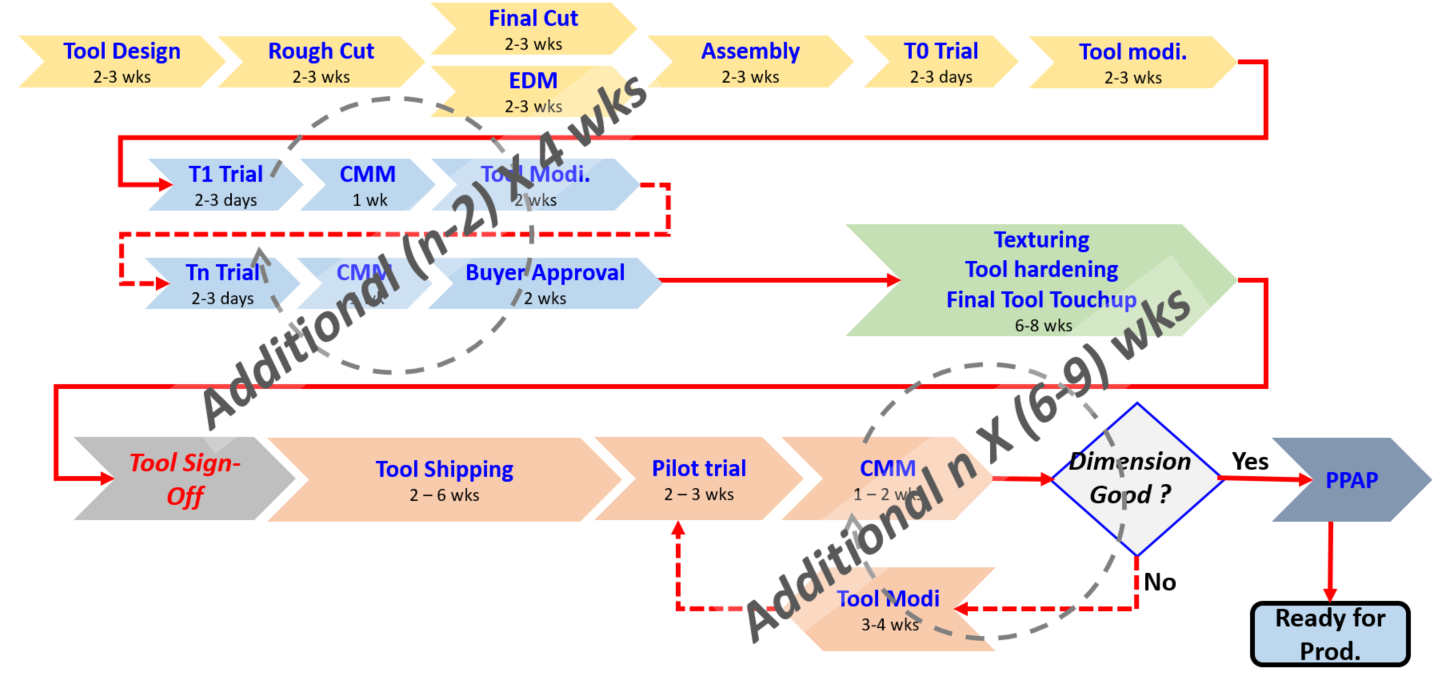

We wanted to make it to be as easy as possible for our customers to switch from virgin to our recycled materials. With the advanced injection molding simulation capabilities, we study not only optimal filling, packing and cooling, but also part shrinkage and warpage behavior accurately. Followed by this process optimization process, the results demonstrated that our Ecolon and Wellamid recycled resin is a strong performer in structural strength and stiffness and has a better flow and cooling profile, leading to remarkably reduced cycle times.

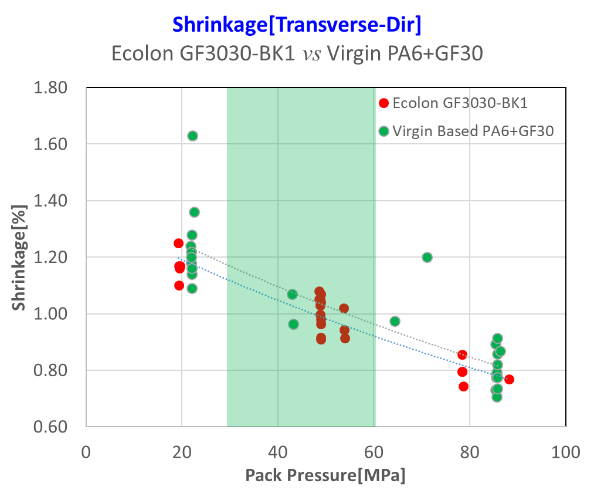

PRET’s state-of-the-art injection molding simulation support help customers to reduce injection mold tool development and debug period dramatically without needs for prototype tooling phase by helping ideal tooling concept, gate scenario and resulting shrinkage adjustment and warpage control strategy from the beginning. This also helps to avoid future manufacturing defects and to improve productivity by reducing cycle time and by lowering scrap rates.

Fig.1 Conventional injection mold tool build process

(Requires multiple tuning loops of “CMM → tool modification → molding trial”)

Fig.2 PRET’s Injection Molding Simulation Process to support customers to reduce tuning loops

● FEA : Structural, NVH, thermal, creep and fatigue analysis for new product and application development

PRET understands the importance of making an efficient design and validation approach both less expensive and timely manner. In particular, to thermoplastics, validating its structural design in advance by performing structural analysis, NVH and thermal analysis, creep, fatigue and impact analysis as required is an essential step in the design process to reduce product, development cost as well as to shorten entire product development period. PRET have numerous record of accomplishment to support customer projects with full set of FEA analysis package as required during each development phase, and our timely FEA analysis support have been contributing on-time project launch to customers.

PRET CAE cooperate with customers under proactive partnership and our goal is to provide valuable and meaningful design solution in time, and eventually to exceed customer’s expectation.

Please contact us to experience our State-of-the-art CAE capabilities.

Fig.3 Demonstration of PRET CAE support capabilities

Fig.4 PRET CAE support map during each development phase